A robot arm loads hot metal cases into the Erie 1 Press at Scranton AAP in Pennsylvania. This is one of the steps in the production chain that can be simulated using the digital twin of the Scranton AAP. (Photo courtesy of PL JS)

Army is Leveraging Digital Engineering to Modernize Munition Production Across the Industrial Base

by Daniel Viaud and Louis Colucci

Digital engineering and modeling and simulation (M&S) are transformative approaches that enable precision, efficiency and innovation in munitions production and warfighter capabilities. By integrating advanced digital tools and data-driven methodologies, the Army can streamline design, testing and manufacturing processes while reducing costs and timelines. Implementing these best practices ensures enhanced operational readiness, improved facility performance and a competitive edge on the modern battlefields.

Upon publication of DOD Instruction 5000.97, “Digital Engineering”, in December 2023, Project Lead Joint Services (PL JS) launched a dual-phased approach with the objective of using digital engineering best practices to baseline the existing state of the Government Owned, Contractor Operated (GOCO) Army Ammunition Plants (AAPs) and identify production process improvements via systems modeling language (SysML)—a general-purpose modeling language used in Model-Based Systems Engineering—architectures. Since the beginning of World War II, the Army’s GOCO facilities have continued to serve a pivotal role in protecting our nation’s security through the manufacturing of critical munitions including but not limited to energetics, small caliber ammunition and high explosive artillery. PL JS is responsible for managing the modernization of these strategically important facilities as part of the Joint Program Executive Office for Armaments and Ammunition (JPEO A&A) mission to achieve efficiencies of scale in the production of critical munitions for all service branches as the Single Manager for Conventional Ammunition. The JPEO A&A is overseeing a massive modernization effort across the Organic Industrial Base to bring our munitions and energetics production capability into the 21st century. Therefore, it has become the ideal use case to implement digital engineering and M&S to capture industrial knowledge, identify process bottlenecks and throughput capacities and better inform leadership on future modernization investments across the enterprise.

TAKING A PHASED APPROACH

Phase I consisted of a dual-faceted approach with the first component being a comprehensive deep dive into an interconnected digital engineering ecosystem software solution. The digital engineering ecosystem enables the digital thread, which is an extensible, configurable component of enterprise-level framework that seamlessly connects authoritative technical data, software, information and knowledge in enterprise data-information-knowledge systems. Leveraging the digital thread, PL JS decision makers can access, integrate and transform disparate data into actionable information within a centralized authoritative source of truth. The digital engineering ecosystem serves as the centralized authoritative source of truth that supports the collection, management and analysis of all digital information. PL JS will utilize the configured user interface to interact with the various connected tools to access the digital thread, manage models and collaborate on product development.

The second major component revolves around creating digital twins of the as-is configuration of the GOCO facilities and production lines. These digital twins are a foundational effort that provides the Army with an in-depth view and understanding of specific activities and overall operations throughout the system life cycle. The digital twins are built in SysML-based MagicDraw software and they are currently being used to simulate the end-to-end product and data flow within the AAPs and their respective manufacturing lines. As the Army looks to replenish stockpiles and onshore critical chemical production, the process models play a key role in future competition, project awards and strategic allocation of resources.

Phase II is currently underway, and the main focus is on further development of the digital twins and incorporating the capability to perform what-if scenarios within the models. Over the past year, there has been significant progress made on creating the digital twins of the complete M795 artillery shell production cycle, spanning from metal parts manufacturing at Scranton AAP to the Load, Assemble and Pack (LAP) operations at Iowa AAP. During this Phase II refinement, simulations were created and tested to identify bottlenecks, conduct throughput analyses and explore what-if scenarios. These what-if scenarios include use cases such as surge capacities, facility configuration or modification impacts, and building utilization rates based on increased or decreased demand, and production forecasting pre and post modernization investment. These capabilities equip PL JS with essential tools to guide future modernization efforts and investment decisions accurately, efficiently and swiftly.

FROM THEORY TO PRACTICE

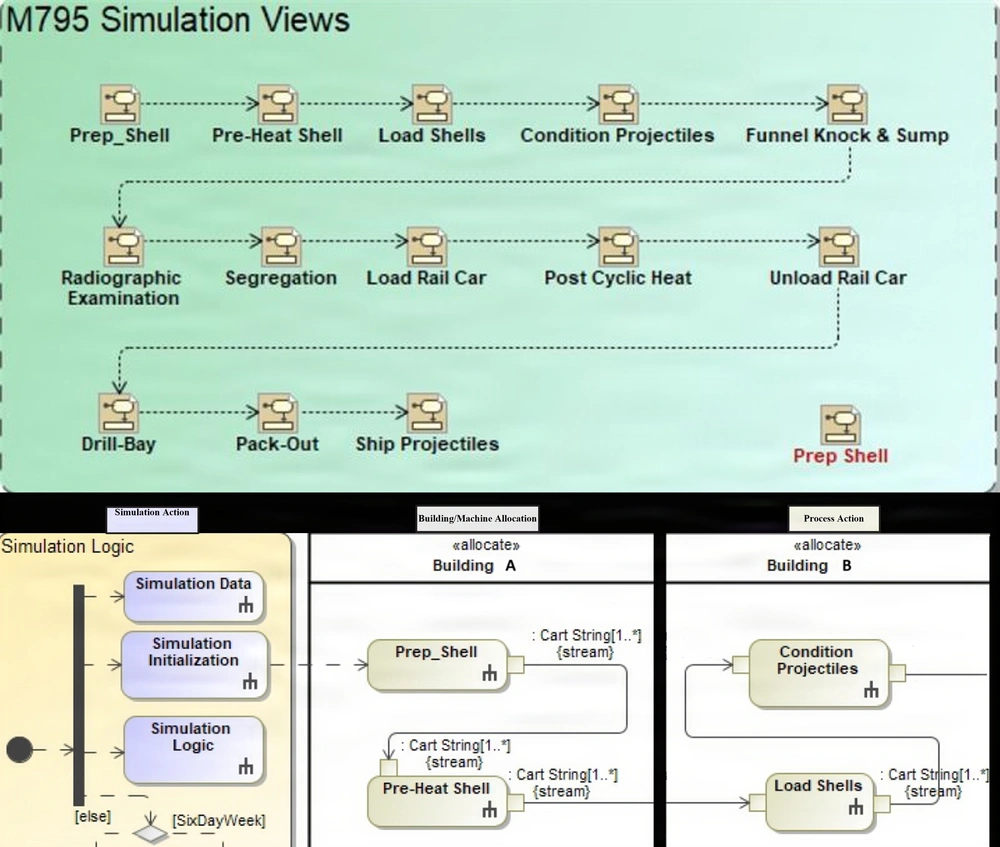

For example, the Iowa AAP M795 baseline digital twin was established in June 2024. This model focuses on 3A line at Iowa, which encompasses all buildings involved in the LAP process for the M795 artillery shell. The model consists of a high-level block diagram summarizing the activities within each building along with their allocated equipment that allows the user to select any block and explore the higher fidelity internal block diagrams for a closer view of operations. Figure 1 is an example of the high-level block diagram consisting of swim lanes that show Building A preps and pre-heats the shells prior to moving to Building B for loading and conditioning of the cart of shells. The rake icon shown within the prep shell element indicates further decomposition of the process is included within that element and the user can view that inner structure.

M795 Diagram

M795 high-level diagram of an artillery production simulation represents the cutting edge of digital engineering and is a model for future manufacturing design and modernization. (Graphic by Daniel Viaud)

The simulation also enables predictive analysis for various work shift scenarios (e.g., 8 hours, 24 hours or 45 days) and calculates the net throughput of shells produced during that timeframe. Tokens representing shells, carts or cart strings are tracked throughout the manufacturing process, with bottlenecks flagged by numeric counters on affected blocks. To address bottlenecks identified during simulations, various what-if scenarios were created, with one being to modify the line configurations by adding equipment. Once the updated equipment was incorporated into the model, an impact analysis was completed to study the effects of throughput over the desired shift schedule. This approach has provided critical data to confirm potential bottleneck resolutions and estimate theoretical throughput improvements from potential investments prior to any project awards.

CYBERSECURITY IS A MUST

Integration of digital engineering is not without its challenges. Ensuring that cybersecurity requirements are both implemented and continuously monitored is of the utmost importance in establishing a comprehensive digital ecosystem. The very data that is highly valued by the government is also a prime target for adversaries seeking competitive advantage or others harboring far more malicious intentions. A common misconception is that security can render a system less functional. However, it is security itself that ensures the system can remain an operational asset for years to come. Balancing cybersecurity with usability is an essential component of any ecosystem.

At a high level, the primary focus is on safeguarding the confidentiality, integrity and availability of the system(s) and the data they generate. Traditionally, an organization’s risk appetite would dictate which of these focus areas takes precedence, for example, prioritizing confidentiality over availability. However, due to the multi-faceted nature and impact of digital transformation, all three areas may hold equal or near-equal importance.

Adhering to a comprehensive cybersecurity methodology is paramount in ensuring the long-term success of a digital engineering ecosystem. Balancing security with usability while understanding the complete risk profile is essential to operational success both during initial implementation and future sustainment.

CONCLUSION

Digital engineering simulations, backed by effective cybersecurity, can serve as a vital acquisition tool for optimizing plant efficiency through the validation of modernization project designs. With this data in hand, leadership can be better informed of facility impacts for varying capacity requirements enabling them to make better decisions on how to reach capacity changes. Finally, digital constructions of the complex and intricate framework of the Army’s munitions and energetics industrial base help capture industrial knowledge into a usable form for planning and decision-making. This level of insight is only available through digital engineering efforts, which is why digital engineering will become the de facto method of managing the Army’s production facilities.

For more information, go to https://www.cto.mil/news/digital-engineering-practice/.

DANIEL VIAUD is a digital engineering lead for PL JS, JPEO A&A at Picatinny Arsenal. He holds an M.S. in mechanical engineering with a concentration in mechanical systems from the University of Central Florida, a B.S. in mathematics from St. Thomas Aquinas College and a B.S. in mechanical engineering from Manhattan College.

LOUIS COLUCCI is a cybersecurity engineer for PL JS, JPEO A&A at Picatinny Arsenal. He holds an M.S. in computer science with a concentration in information technology from Montclair State University, a B.A. in philosophy and a B.S. in business management both from William Paterson University. He also holds CISSP, CISA and CDPSE certifications.